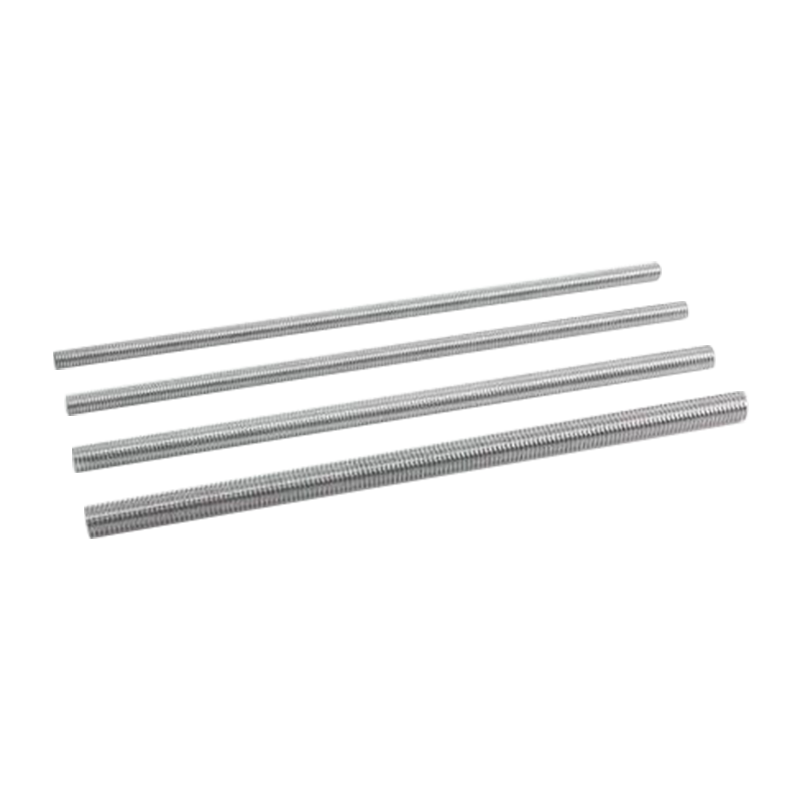

Full Thread Screw

Full Thread Screw Manufacturers

full thread screw, also known as a fully threaded screw, is a type of fastener that has threads that run along the entire length of the screw shaft. Unlike partially threaded screws, which have a smooth section near the head, full-thread screws have continuous threads from the tip to the head. The continuous threads of a full-thread screw provide improved grip and holding power. They distribute the load more evenly along the entire length of the screw, making them suitable for applications where a stronger hold is required. With threads running throughout the screw's length, a full-thread screw offers enhanced stability and resistance to loosening. This can be particularly beneficial in applications where vibration or movement is a concern.

Jiaxing Paide Import and Export Trading Co., Ltd.

Solutions suitable for all industries and factories.

Jiaxing Paide Import and Export Trading Co., Ltd. as China Wholesale Full Thread Screw Manufacturers and Custom Full Thread Screw Suppliers located in the Jianshan New Area of Haining, Jiaxing, it is rich in resources, convenient in transportation, and has a very advantageous geographical location, which provides natural conditions for the development of an export-oriented economy. The company specializes in developing and manufacturing various series of screw products and various fasteners, with a one-stop processing and heat treatment service, complete self inspection equipment, and strict quality control. The company was founded in 2000, with a total investment of over 100 million yuan, covering an area of 25 acres, and an annual output of over 10000 tons.

Honor

-

honor

honor -

honor

honor

News

-

2024-05-01

When it comes to fasteners for specific materials like rice fiberboard, understa...

View More -

2024-04-25

When it comes to fasteners designed for durability, corrosion resistance, and ef...

View More -

2024-04-16

In the realm of construction and carpentry, precision and aesthetics are paramou...

View More -

2024-04-11

U-bolts, also known as U-shaped screws, are a fundamental type of fastener with ...

View More -

2024-04-07

When it comes to fastening components in construction, manufacturing, or DIY pro...

View More -

2024-03-26

Hexagonal screw bolts, also known as hex bolts or hexagonal head bolts, are wide...

View More

Industry Introduction

Are there special considerations for Full Thread Screw in high-stress or load-bearing applications?

Yes, there are special considerations for using full thread screws in high-stress or load-bearing applications. Full thread screws have threads that run along the entire length of the shaft, providing a continuous grip along the fastened material. When using full thread screws in high-stress or load-bearing situations, the following considerations are important:

Material Strength: Ensure that the material being fastened can handle the intended load or stress. The combined strength of the material and the full thread screw should be sufficient to withstand the expected forces.

Screw Material: Choose full thread screws made from a material that matches or exceeds the strength requirements of the application. High-strength materials like stainless steel or alloy steel are often preferred for demanding applications.

Screw Size: Select the appropriate screw size and length to achieve proper thread engagement and to accommodate the thickness of the materials being fastened.

Pre-Drilling: In some cases, pre-drilling pilot holes may be necessary, especially when working with hardwoods or dense materials. Pre-drilling helps prevent splitting and facilitates easier screw installation.

Tightening Torque: Avoid over-tightening the screws, as this can lead to stress concentrations or material damage. Follow the manufacturer's recommended tightening torque to achieve the desired clamping force without causing deformation.

Spacing and Quantity: Plan the spacing and quantity of the full thread screws based on the load distribution and the overall structural requirements of the application.

Avoid Off-Axis Loading: Try to minimize off-axis loading on the screws. High-stress applications may require additional support, such as using multiple fasteners or adding reinforcement.

Professional Consultation: For critical load-bearing applications, consider consulting with a structural engineer or a professional with expertise in fastening and structural design. They can help ensure that the chosen full thread screws and fastening methods meet the required safety and performance standards.

Testing and Verification: In some cases, load testing or verification of the fastener's performance may be necessary to ensure that it meets the required load-bearing capacity.

Environmental Factors: Consider environmental factors like temperature, moisture, and corrosive agents. For outdoor or harsh environments, choose full thread screws with appropriate corrosion-resistant coatings.

Can Full Thread Screw be used in conjunction with other fasteners, such as nuts and bolts?

Yes, full thread screws can be used in conjunction with other fasteners, such as nuts and bolts, depending on the specific requirements of the application. This combination of fasteners is often referred to as "bolt and screw assembly" and is commonly used in various construction, woodworking, and mechanical applications.

Here are some scenarios where full thread screws can be used in conjunction with nuts and bolts:

Assembly of Components: Full thread screws can be used alongside nuts and bolts to assemble components together. The screws provide a threaded hole, and the nuts and bolts provide a threaded rod or shank. This combination allows for a secure and adjustable connection between the components.

Joints Requiring Disassembly: When joining materials that may need to be disassembled later, using a combination of screws, nuts, and bolts offers a reversible connection. This is especially useful in cases where maintenance or repairs may be required.

Mounting and Fixing: In some situations, using a combination of screws, nuts, and bolts allows for flexible mounting and fixing solutions. For example, you might use full thread screws to attach brackets to a surface and then use nuts and bolts to attach another component to the brackets.

Increased Holding Power: When a joint or connection requires additional holding power, combining screws, nuts, and bolts can provide a more robust and secure fastening solution.

Unique Design Requirements: Certain applications may have unique design requirements that call for the use of different fasteners together to achieve the desired result.

Additionally, consider the material and corrosion resistance of the fasteners, especially when used in outdoor or corrosive environments. Using compatible and high-quality fasteners ensures the longevity and performance of the assembly.

English

English  English

English 中文简体

中文简体 русский

русский