Stainless Steel Self-Tapping Screws

Stainless Steel Self-Tapping Screws Manufacturers

Stainless steel self-tapping screws are a type of fastener commonly used in construction, woodworking, and various other applications. They are designed to create their own threads as they are driven into a material, eliminating the need for a pre-drilled hole. The screws are made from stainless steel, which provides corrosion resistance and durability. Self-tapping screws have a unique thread design with a sharp, pointed end. As you drive the screw into the material, the sharp point creates a thread groove, allowing the screw to tap its own hole. These screws are suitable for use in various materials, including wood, plastic, and thin metal sheets. They are commonly used in applications such as fastening metal roofing, assembling furniture, securing electrical boxes, and installing hardware.

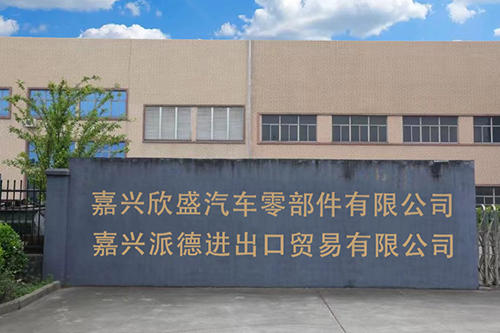

Jiaxing Paide Import and Export Trading Co., Ltd.

Solutions suitable for all industries and factories.

Jiaxing Paide Import and Export Trading Co., Ltd. as China Wholesale Stainless Steel Self-Tapping Screws Manufacturers and Custom Stainless Steel Din7981 Screws Suppliers located in the Jianshan New Area of Haining, Jiaxing, it is rich in resources, convenient in transportation, and has a very advantageous geographical location, which provides natural conditions for the development of an export-oriented economy. The company specializes in developing and manufacturing various series of screw products and various fasteners, with a one-stop processing and heat treatment service, complete self inspection equipment, and strict quality control. The company was founded in 2000, with a total investment of over 100 million yuan, covering an area of 25 acres, and an annual output of over 10000 tons.

Honor

-

honor

honor -

honor

honor

News

-

2024-05-01

When it comes to fasteners for specific materials like rice fiberboard, understa...

View More -

2024-04-25

When it comes to fasteners designed for durability, corrosion resistance, and ef...

View More -

2024-04-16

In the realm of construction and carpentry, precision and aesthetics are paramou...

View More -

2024-04-11

U-bolts, also known as U-shaped screws, are a fundamental type of fastener with ...

View More -

2024-04-07

When it comes to fastening components in construction, manufacturing, or DIY pro...

View More -

2024-03-26

Hexagonal screw bolts, also known as hex bolts or hexagonal head bolts, are wide...

View More

Industry Introduction

How do you properly install Stainless Steel Self-Tapping Screws to ensure effective and secure fastening?

Properly installing stainless steel self-tapping screws is crucial to ensure effective and secure fastening. Follow these steps for successful installation:

Select the Right Screw: Choose the appropriate stainless steel self-tapping screw for your application. Consider factors such as the material you're fastening into, the thickness of the materials, the screw size, and the specific type of self-tapping screw (e.g., Phillips, Torx, or square drive).

Drilling Pilot Holes (if necessary): In some cases, especially when working with hard or dense materials, it's beneficial to drill pilot holes before installing the self-tapping screws. The pilot holes should be slightly smaller in diameter than the screw's shank to provide optimal thread engagement.

Prepare the Materials: Align the materials to be joined and ensure they are flush and level. If using multiple screws, make sure they are evenly spaced for even distribution of the load.

Insert the Screw: Hold the screw using an appropriate driver bit (e.g., Phillips, Torx) and apply downward pressure to engage the screw's tip into the material. Begin turning the screw clockwise while exerting gentle downward pressure.

Allow the Screw to Tap: As you turn the screw, the sharp point of the self-tapping screw will cut its own thread into the material. Apply consistent and firm pressure, but avoid over-tightening.

Use Correct Torque: Do not over-tighten the screw, as this can lead to damage to the screw, the material, or a weakened connection. Use a torque-limiting driver or a torque wrench if needed to achieve the recommended tightening torque.

Check for Flushness: Ensure that the screw head sits flush with the material's surface. If it is too recessed, the screw may not provide adequate clamping force.

Vibration Resistance (Optional): For applications prone to vibrations or where loosening is a concern, consider using self-tapping screws with a thread-locking feature or use a drop of thread-locking adhesive on the threads.

Avoid Over-Drilling: Be cautious not to over-drill the hole, as this may reduce the thread engagement and compromise the screw's holding strength.

Inspection and Testing: After installation, inspect the screws and the fastened connection to ensure proper alignment and security. If possible, perform load testing or apply stress to verify the effectiveness of the fastening.

Remember that stainless steel self-tapping screws are intended for one-time installation, as they cut their own threads into the material. Attempting to remove and reuse self-tapping screws can lead to diminished performance and holding strength.

Are there any alternatives to Stainless Steel Self-Tapping Screws for specific applications?

Yes, there are several alternatives to stainless steel self-tapping screws for specific applications, depending on the requirements and characteristics of the project. Some of these alternatives include:

Regular Threaded Screws: Regular threaded screws, also known as machine screws or wood screws, can be used in applications where pre-drilled pilot holes are available. They are available in various materials, including stainless steel, carbon steel, and brass, and are suitable for use in different types of materials, such as wood, metal, and plastics.

Thread-Cutting Screws: Thread-cutting screws, also called thread-forming screws, create threads by displacing material rather than cutting it. They work well in softer materials like plastic or thin metal, and they provide strong, secure threads with excellent vibration resistance.

Bolt and Nut Assemblies: Instead of using self-tapping screws, you can use bolts and nuts for applications where a strong, removable connection is required. This allows for more flexibility in disassembly and reassembly.

Self-Drilling Screws: Self-drilling screws, also known as Tek screws or self-drilling sheet metal screws, have a drill-like point and do not require pre-drilled pilot holes. They are designed for fastening metal to metal or metal to wood and offer efficient and time-saving installation.

Lag Screws: Lag screws, also called lag bolts, are heavy-duty screws with a hex head. They are used for securing wood to wood or wood to metal connections. Lag screws require pre-drilled pilot holes and offer high load-bearing capacity.

Anchor Bolts: Anchor bolts are used to secure objects to concrete or masonry surfaces. They provide excellent holding strength in applications where traditional screws or fasteners may not be suitable.

Nails and Rivets: In some situations, nails and rivets can be used as alternatives to screws for fastening materials together. They are commonly used in woodworking, metalworking, and construction projects.

Welding: In certain cases, welding may be used to permanently join materials together, especially in metalworking and fabrication projects.

English

English  English

English 中文简体

中文简体 русский

русский