Self-Tapping Screw

Round Head Cross Self-Tapping Screw Manufacturers

A self-tapping screw is a type of fastener that has the ability to create its own mating threads as it is driven into a material, without the need for a pre-existing hole with matching threads. It is designed to tap its own hole as it is screwed into the material, hence the name "self-tapping."Self-tapping screws have a pointed tip and sharp, aggressive threads along the length of the screw. As the screw is rotated and pressure is applied, the threads cut into the material, creating the mating threads. This tapping action allows the screw to securely fasten itself to the material. These screws are commonly used in situations where it would be difficult or impractical to create pre-drilled holes, such as in sheet metal or plastics. They are often used in construction, automotive, electronics, and various other industries.

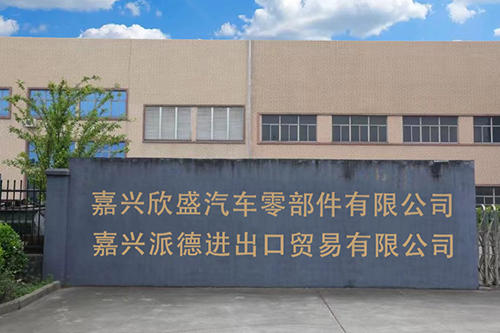

Jiaxing Paide Import and Export Trading Co., Ltd.

Solutions suitable for all industries and factories.

Jiaxing Paide Import and Export Trading Co., Ltd. as China Wholesale Round Head Cross Self-Tapping Screw Manufacturers and Custom Countersunk Cross Self-Tapping Screw Suppliers located in the Jianshan New Area of Haining, Jiaxing, it is rich in resources, convenient in transportation, and has a very advantageous geographical location, which provides natural conditions for the development of an export-oriented economy. The company specializes in developing and manufacturing various series of screw products and various fasteners, with a one-stop processing and heat treatment service, complete self inspection equipment, and strict quality control. The company was founded in 2000, with a total investment of over 100 million yuan, covering an area of 25 acres, and an annual output of over 10000 tons.

Honor

-

honor

honor -

honor

honor

News

-

2024-05-01

When it comes to fasteners for specific materials like rice fiberboard, understa...

View More -

2024-04-25

When it comes to fasteners designed for durability, corrosion resistance, and ef...

View More -

2024-04-16

In the realm of construction and carpentry, precision and aesthetics are paramou...

View More -

2024-04-11

U-bolts, also known as U-shaped screws, are a fundamental type of fastener with ...

View More -

2024-04-07

When it comes to fastening components in construction, manufacturing, or DIY pro...

View More -

2024-03-26

Hexagonal screw bolts, also known as hex bolts or hexagonal head bolts, are wide...

View More

Industry Introduction

What are the different types of Self-Tapping Screw available on the market?

Self-tapping screws, also known as self-tapping or thread-forming screws, are screws designed to create their own threads as they are driven into a material, without the need for a pre-drilled hole or a nut. They come in various types, each designed for specific applications and materials. Some of the common types of self-tapping screws available on the market include:

Sheet Metal Screws: These screws are designed for use in thin metal sheets and have sharp, fine threads that create their own threads in the material as they are tightened. They are commonly used in HVAC ducts, electrical boxes, automotive applications, and other sheet metal assemblies.

Wood Screws: Wood screws have coarse threads and are designed for use in wood and wood-like materials. They are available in various head styles, such as flat head, round head, and pan head. Wood screws may also have special features like a sharp point or a gimlet tip to help them penetrate the wood easily.

Deck Screws: Deck screws are specifically designed for outdoor decking applications. They have corrosion-resistant coatings to withstand exposure to weather and are often made from materials like stainless steel or coated steel.

Drywall Screws: These screws have bugle-shaped heads and coarse threads. They are designed for fastening drywall to metal or wood studs. Drywall screws have a sharp point to penetrate the drywall without the need for pre-drilling.

Concrete Screws: Concrete screws, also known as masonry screws, are designed for use in concrete, brick, or block materials. They have a special thread design and often come with a corrosion-resistant coating for durability in harsh environments.

Plastic Screws: Plastic screws are used for fastening plastic materials. They have unique thread designs that help prevent cracking or damaging the plastic during installation.

Self-Drilling Screws: These screws, as mentioned earlier, have a drill-like point and are often used for metal-to-metal applications. They can create their own pilot holes as they are driven into the material.

Furniture Screws: Furniture screws are designed for assembling furniture. They often have decorative heads and come in various lengths to accommodate different furniture thicknesses.

License Plate Screws: These screws are small self-tapping screws designed specifically for attaching license plates to vehicles.

Thread-Cutting Screws: Thread-cutting screws have sharp cutting edges and are used in softer materials like plastic or soft metals to create mating threads.

These are just some of the common types of self-tapping screws available on the market. Each type is designed to serve a specific purpose and provide efficient fastening in particular materials and applications. When choosing the right self-tapping screw for a project, it's essential to consider factors like material compatibility, thread type, screw size, and the environmental conditions the screws will be exposed to.

How do Self-Tapping Screwwork? What is the mechanism behind their self-drilling feature?

Self-tapping screws work by employing a clever thread design and a cutting or drilling action, allowing them to create their own mating threads in the material they are being driven into. The mechanism behind their self-drilling feature involves the following steps:

Drill-like Point: Self-tapping screws have a unique point at the tip, which is often shaped like a drill bit. This point is designed to be sharp and capable of cutting through the material as the screw is inserted.

Thread Design: The threads of self-tapping screws are designed to have a flute-like or helical shape. These threads have cutting edges that resemble those of a tap, which is a tool used for cutting internal threads in a hole.

Thread Formation: As the self-tapping screw is driven into the material, the drill-like point creates a small pilot hole by cutting through the material. The threads of the screw then engage with the walls of this pilot hole.

Cutting Action: As the screw continues to be turned, the helical threads cut into the material, essentially forming mating threads within the pilot hole. The displaced material from the cutting action is forced outward, creating the necessary space for the screw's threads to fit in.

Friction and Holding Power: Once the self-tapping screw has fully engaged with the material and the mating threads are formed, the screw generates friction and creates a tight, secure hold in the material.

By combining the drill-like point and the specially designed threads, self-tapping screws eliminate the need for pre-drilling or the use of nuts in certain applications. This feature significantly speeds up the fastening process, making self-tapping screws more efficient and practical for various projects.

It's important to note that self-tapping screws are designed for specific materials, and using them in materials not suited for their thread design can lead to inefficient or weak connections. Therefore, it's crucial to choose the appropriate type of self-tapping screw based on the material and application requirements to ensure proper functionality and performance.

English

English  English

English 中文简体

中文简体 русский

русский